Prepress

Before the printing process begins, our customers deliver their projects digitally as a read-only PDF file. We receive proof prints that are produced digitally as well. Before printing, we need to make sure that files and printing process are compatible. Though there are many solutions available, it is essential to take the type of printing process and the selected paper into particular account. We provide either a plotter print (a digital version of the anticipated paper print), or a low resolution file from a PDF or from a server that allows you to check the expected end result, and, if you wish, make adjustments.

Digital printing

This printing process is fully digitalized as the information is printed directly from the computer. Suitable for smaller quantities.

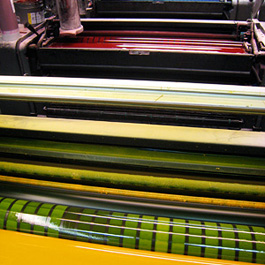

Sheet-fed offset

Printing is performed directly from plates to separate sheets. Usually, one sheet at a time is printed, using 4 - 6 colors. Suitable for medium-size quantities.

Web offset

This is done by transferral of the ink color from printing plates to rubber blankets, and then directly in 4 colors onto paper. Using this process, roll paper is printed on both sides in a rotary press, and folded to signatures while still in the printing press. Another option is to wire stitch or glue the printed matter with self-covers, and then trim it while it is still in the printing press. Suitable for larger quantities.

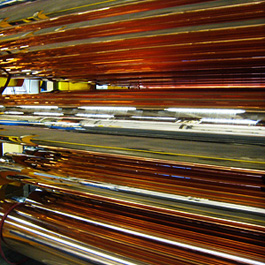

Gravure

Using the gravure process means the paper absorbs the ink colors directly from digitally engraved copper cylinders. The process is performed in a rotary press with 4-color printing on the front and back sides of the paper. Suitable for larger quantities. The gravure process can be used with many different paper qualities – from newsprint to wood free paper – in 45g to 100g grammage, and up to approx. 180 pages in one run. There is also the option to wire stitch or glue the printed matter with self-covers, and then trim it while it is still in the printing press.

Scratch & sniff

For this process we apply perfume capsules in a printing unit so that the fragrance is transferred directly to the paper. Suitable for cosmetic products, as touching the paper allows the fragrance to diffuse. Scratch & sniff can be produced in offset as well as in gravure processes.

Finishing

We perform anything from folding to wire stitching or perfect binding. Naturally, our products include inserts or CD discs, and we can apply plastic-coating or wrap your printed material with streamers, among other things.

Additional services

We also produce books with hardback or paperback binding. For customers who want customized covers, our services include: laminating, water based varnishing, embossing, punching, head & tail bands, gilt edges, partial UV-varnishing, and more.